Appliance couplers

Hazardous area connectors

'Buccaneer' sealed connectors

General purpose connectors and accessories

Finder 78 Series / OPTA Power Supplies

78 Series Switch Mode Power Supplies

The 78 Series is a range of low profile

modular power supplies for electrical

cabinets and industrial switch mode power

supplies. KNX power supply with rated output

30V DC 640mA available.

Function & Features (according to type):

Applications:

OPTA Power Supply

Optimal Performance and Maximum Protection with Finder's Power Supply Type 78.12….2482, specifically designed for use with OPTA

Providing the power needed to operate Finder’s PLRs (Programmable Logic Relays), the OPTA power supply provides a 24 V DC supply voltage, and can handle high inrush currents.

The OPTA power supply is also surge protected – from surges attributable to the power grid, overheating, short-circuits, and those generated by other connected devices – ensuring a reliable and durable product.

The OPTA power supply is also suitable for use in SELV (safety extra-low voltage) systems (according to EN 60950). The Type 78.12….2482 has attained ENEC and UL certifications – attesting its compliance with international safety standards.

Here are some of its features and specifications.

Features & Specifications:

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

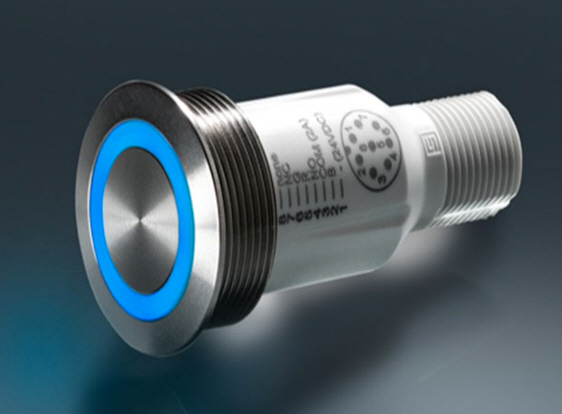

MSM II-Switch with M12 Connector

With the new switch from the MSM II family with M12 connector (8 pins), Schurter is focusing on a solution that has been specially developed for demanding industrial and commercial applications. Thanks to the M12 connector system, robust construction, and integrated RGB illumination, this switch combines maximum reliability, functionality, and modern design in a compact unit.

The standardized M12 connector ensures fast, secure, and error-free installation—without any complicated wiring. Thanks to the fixed pin assignment, wiring errors are effectively avoided, which not only simplifies installation but also speeds it up considerably.

The mechanical design is made for permanent industrial use—shockproof, vibration-resistant, and resistant to tough environments. This means the switch will keep working reliably for years, even in extreme conditions.

The three-color RGB illumination provides clear status indication or individual signals. Example: green = active; red = off; flashing orange = error condition. This makes the switch ideal for machine controls, control systems, or user interfaces.

The new Schurter MSM II M12 switch is suitable for applications where installations must be made quickly, easily, and safely. It is used in industrial automation, machine and plant engineering, as well as in public and commercial areas where clear signaling and high reliability are required.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

© E. Preston (Electrical) Ltd 2026.

UK distributor of electrical and electronic components.