Johnson Electric offers a wide range of power pump subsystems, utilizing various motor technology platforms. Our synchronous, high voltage DC, and EC pumps are engineered for high power, low noise, and long-life performance.

We provide customized applications engineering to adapt and enhance performance based on unique design requirements. With the acquisition of Stackpole International, our automotive pump portfolio now includes engine and transmission pump technologies, complementing our market leadership in fuel and washer pump applications.

Additionally, we deliver durable and reliable valves and cartridges for combi boilers and metering applications, ensuring safety through vertical integration and our proven production system. Trust Johnson Electric for innovative solutions across industrial sectors.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

Data centers are handling and analyzing enormous amounts of information daily. As data generation increases, the heat generated by the data center indispensably increases. This excess heat generated by data centers can harm the hardware including Central Processing Unit (CPUs) and Graphic Processing Unit (GPUs), reducing their performances, or causing complete failures. To ensure optimal operation, it is crucial to select the right cooling solution.

Market Trends:

According to the (Technavio report 2023), the global market for cooling data centers is projected to increase from USD9.5 billion in 2020 to USD22.6 billion by 2025, with a Compound Annual Growth Rate (CAGR) of 18.0%. However, the high energy consumption associated with data center cooling contributes to increased carbon emissions and energy costs. Therefore, businesses are seeking eco-friendly and energy-efficient cooling technologies, such as free cooling, liquid cooling, and artificial intelligence (AI).

Free Cooling:

One of the most popular methods for cooling data centers is free cooling, which utilizes outer air to cool the center, as opposed to traditional air conditioning. However, technology is not suitable for all climates. For instance, in humid areas, free cooling may cause condensation that damages the hardware or necessitates additional cooling during warmer periods.

Liquid Cooling:

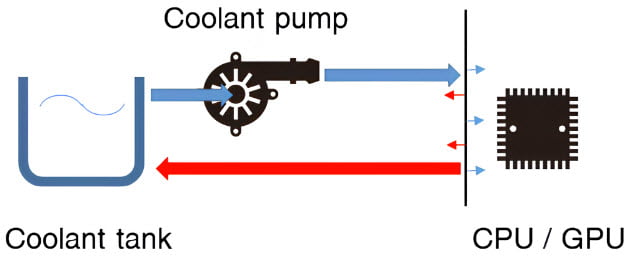

Liquid cooling is gaining popularity in data centers due to its efficiency. Liquid coolant is used to remove heat from the hardware, as liquids offer higher thermal capacity than air resulting in reduced energy consumption. Additionally, liquid cooling fans are quieter than traditional air-cooled fans. As a result, many data centers are turning to this technology to improve their cooling efficiency.

Liquid cooling systems can be classified into two types, namely direct and indirect. Direct liquid cooling involves direct contact between the liquid and hardware, removing heat directly from the source. On the other hand, indirect liquid cooling uses the liquid to cool a heat exchanger, which draws heat from the hardware. Although direct liquid cooling is more effective in removing heat directly from the source compared to indirect liquid cooling, it may require a higher implementation and maintenance cost.

AI-Based Cooling:

AI-based cooling systems utilize sensors to analyze data and optimize temperature and humidity levels within data centers. Furthermore, the systems can predict and prevent potential cooling issues. Implementing AI-based cooling system can reduce energy consumption and enhance cooling efficiency. However, it may involve significant upfront cost and ongoing AI Algorithms development to ensure the accuracy of the real-time data.

In Conclusion, selecting the appropriate cooling solution based on business needs is vital for data centers to ensure optimal performance, reduce energy consumption, and minimize the risk of hardware damage and downtime.

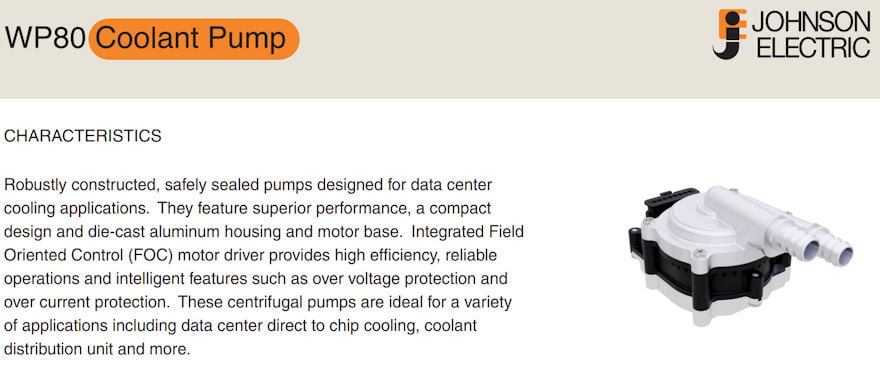

As an industry leader, Johnson Electric offers liquid coolant pumps such as WP80 BLDC Coolant Pump using Brushless DC (BLDC) motors technology and on-board electronic controls that provide intelligent pump operation and safety features.

The Brushless DC (BLDC) motors, with their exceptional features such as speed stability, high efficiency, reliability, and long lifespan, are considered the most suitable option for pump drives in Coolant Distribution Units (CDUs) utilized in data centers. The brushless motor technology is highly compatible with in-row or rack-mounted CDUs and on-board electronic controls, offering intelligent pump operation and safety features for major automotive OEMs and Tier 1 suppliers in Europe, America, and Asia.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

© E. Preston (Electrical) Ltd 2026.

UK distributor of electrical and electronic components.