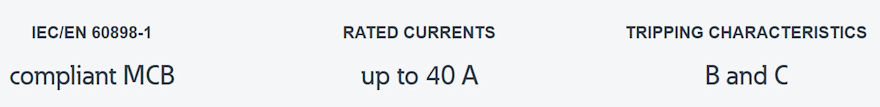

The PLN4 miniature circuit breaker (MCB) is a protective

device that’s equipped with both a thermal and an

electromagnetic release. The former responds in the event

of an overload, while the latter offers protection against

short circuits.

The 1+N-pole MCB is only 1 HP wide and is

available with rated currents from 2 A to 40 A. The switching

capacity is 4.5 kA. The circuit breaker, which is available with

tripping characteristics B and C, is equipped with a red-green

contact-position indicator for indicating the device state.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

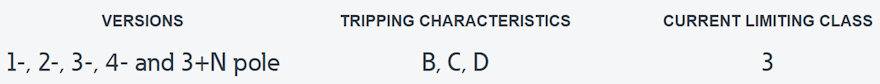

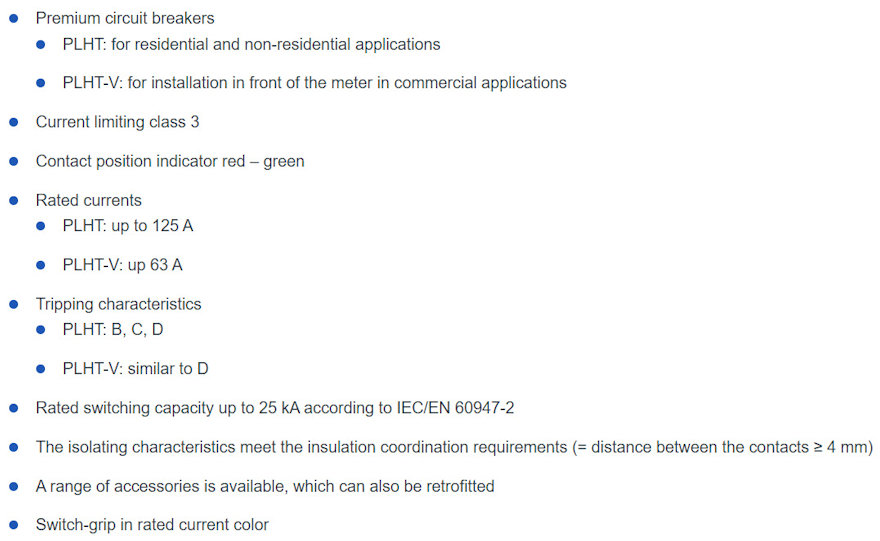

The PLHT miniature circuit breaker is a protective device equipped with both a thermal and an electromagnetic release that is available in 1-, 2-, 3-, 4- and 3+N pole versions. The PLHT is compatible with AC and DC applications up to 60 V with rated currents from 20 A to 125 A and is available with tripping characteristics B, C and D. It has a switching capacity of up to 25 kA.

The PLHT-V is a special 1-pole version of the PLHT miniature circuit breaker for installation in front of the meter in commercial applications. The PLHT-V is compatible with AC and DC applications up to 60 V with rated currents from 20 A to 63 A and is available with a tripping characteristic that is similar to type D. This special version has a switching capacity of up to 25 kA.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

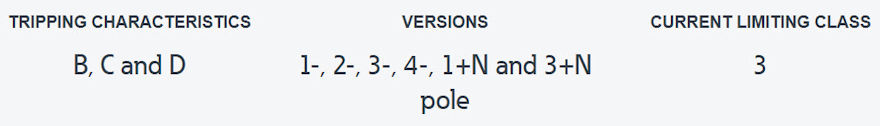

The FAZ6 miniature circuit breaker is a protective device equipped with both a thermal and an electromagnetic release that is available in 1-, 2-, 3-, 4-, 1+N and 3+N pole versions.

The FAZ6 is available with rated currents of 0.5 A to 63 A. The switching capacity is 10 kA according to IEC/EN 60947-2 and 6 kA according to IEC/EN 60898-1. A guide for secure terminal connection and a 3-position DIN-rail simplify the installation of the circuit breaker.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

The P1-40 Main switches and ON-OFF switches bridge the gap between the P1’s previous maximum rating of 32 A and the P3’s lowest rating of 63 A. It allows for a greater current rating in the compact P1 size.

Eaton's P1-40 centre mounting, flush mounting, surface mounting and rear mounting switching devices are fully IP65-protected, except for its service distribution board option which is IP30-protected.

Eaton’s world expertise in the design, manufacture and specifications of switch-disconnectors ensure that your application will be protected by the best switching solutions available.

IP65-Rated

All of the surface mounting, flush mounting and rear mounting P1-40 Main and ON-OFF switch-disconnectors are fully IP65-rated, except for the service distribution board mounting option which is IP30-rated

Mounting Options

Standards / Approvals

Technical Data

Features and Benefits

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

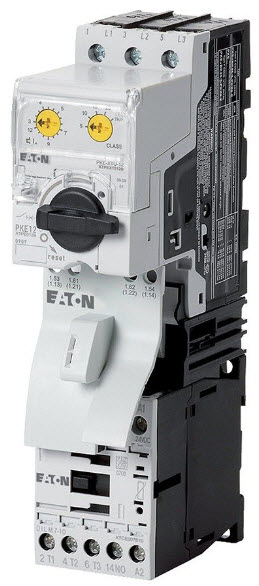

The fuseless motor starters from Eaton's Moeller series have been delivering reliable personal and operational safety in machines and systems for decades.

The motor-starter combinations consist of a motor-protective circuit breaker and a contactor, which can be quickly connected and mounted thanks to the versatile and safe plug-in technology. The compact, fuseless motor starters also make it possible to engineer and build control panels that can be used worldwide.

Connections with just One Clever “Click” – MSC Motor-Starter Combinations with Push-In Technology

The Push-in terminals enable safe and easy control-panel wiring with just one click. Wiring kits for assembly of motor starter combinations up to 32 A are available, with mechanical connecting element and pre-assembled connecting cables for use with DOL starters up to 7.5 kW / 15 kW or reversing starter combinations up to 7.5 kW.

MSC Motor Starters with PKZ up to 32 A

The motor-starter combinations with PKZM0 circuit breaker and DIL contactor are able to handle short circuits up to 50 kA and can be assembled using simple toolless plug connectors. The practical toolless plug connectors are available for Eaton’s DOL and reversing starters up to 15.5 A.

MSC Motor Starters with PKE up to 32 A

The PKE motor-starter combinations can easily be integrated into any automation environment via SmartWire-DT. Data can be transferred directly to the controls and made available across the system. The resulting data transparency increases the efficiency and operational reliability of the drives in the operating environment of the motor-protective circuit breaker.

Smart, Smarter, SmartWire-DT

Our intelligent connection system reduces the wiring costs by up to 85 %. At the same time, it also minimizes installation errors, reduces the planning effort and provides enhanced flexibility during the selection process. The connected devices deliver both analog and digital data, for example on machine states, motor currents or energy consumption.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

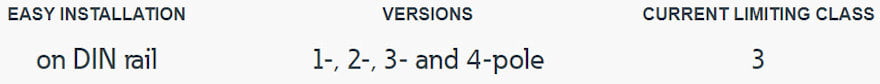

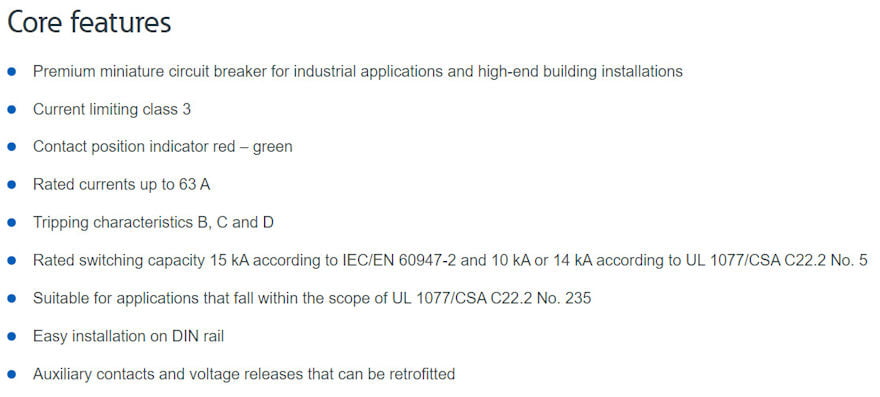

The FAZ-NA / FAZ-RT miniature circuit breaker is a protective device equipped with both a thermal and an electromagnetic release that is available in 1-, 2-, 3- and 4- pole versions.

The FAZ-NA is available with rated currents of 0.5 A to 63 A. The switching capacity is 15 kA according to IEC/EN 60947-2, and 10 kA or 14 kA according to UL 489/CSA C22.2 No. 5, depending on the device type.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

The SPPVR family of surge protection devices (SPDs) is our answer to the growing need for safe and reliable photovoltaic (PV) installations in residential and commercial buildings.

Powerful protection is the first step to ensuring a long lifetime for your equipment and inverters: these SPDs ensure that your system will not be damaged by any overvoltage event on the direct current (DC) side of your PV application.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

.

The FAZ-DC miniature circuit breaker is a protective device equipped with both a thermal and an electromagnetic release that is available in 1- and 2-pole versions. The FAZ is available with rated currents of 2 A to 50 A.

The switching capacity is 10 kA according to IEC/EN 60947-2 The DC rated voltage is 220 V per pole for the 2 A version, and 250 V per pole for the 3 A to 50 A versions. A guide for secure terminal connection and a 3-position DIN-rail simplify the installation of the circuit breaker.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

.

The FAZ miniature circuit breaker is a protective device equipped with both a thermal and an electromagnetic release that is available in 1-, 2-, 3-, 4-, 1+N and 3+N pole versions.

The FAZ is available with rated currents of 0.16 A to 63 A. Depending on the device type, the switching capacity is 15 kA or 10 kA according to IEC/EN 60947-2, 10 kA according to IEC 60898-1, and 10 kA or 5 kA according to UL 1077.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

Win-win with Push-in terminals. The PKZ and DIL range with push-in technology – for faster and more cost-effective wiring

Technicians and purchasers alike love the new Push-in range Wiring has never been more efficient than with Eaton's motor-protective circuit breaker and contactor range. Push-in technology eliminates the need for tools and is trusted by millions of customers around the world. This simple, tool-free wiring method ensures secure connections and maintenance-free contact points, for optimum efficiency during installation and servicing. The xStart solution with Push-in technology, consisting of our DIL contactors and PKZ motor-protective circuit breakers, makes your job easier while offering global compatibility and maximum reliability.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

© E. Preston (Electrical) Ltd 2026.

UK distributor of electrical and electronic components.