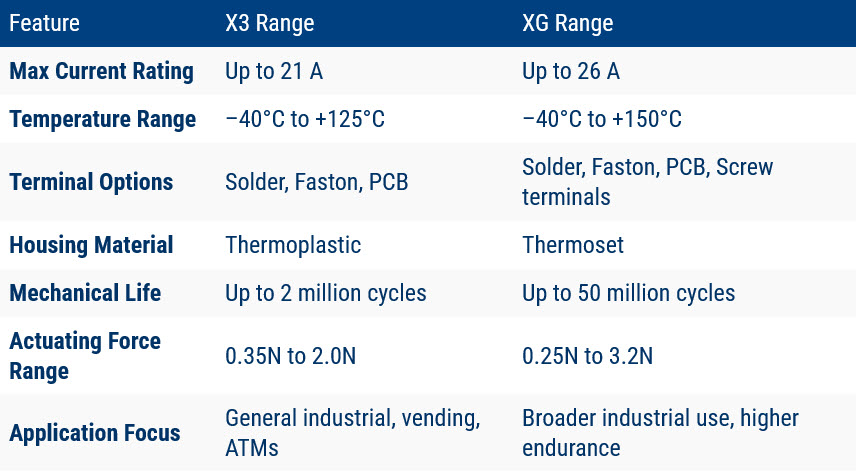

SAIA X3 vs XG Switch Range

Johnson Electric is a leader in microswitch technology, offering precision microswitches under the Saia brand and industrial-rated options under the Burgess brand.

The X3 and XG ranges of MINIATURE microswitches from the SAIA® brand within the Johnson Electric portfolio, are ideal for high-volume, precision switching in compact environments. Both offer snap-action mechanisms and a variety of lever & terminal configurations

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

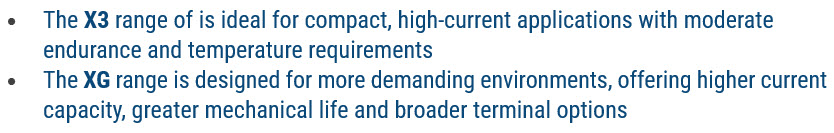

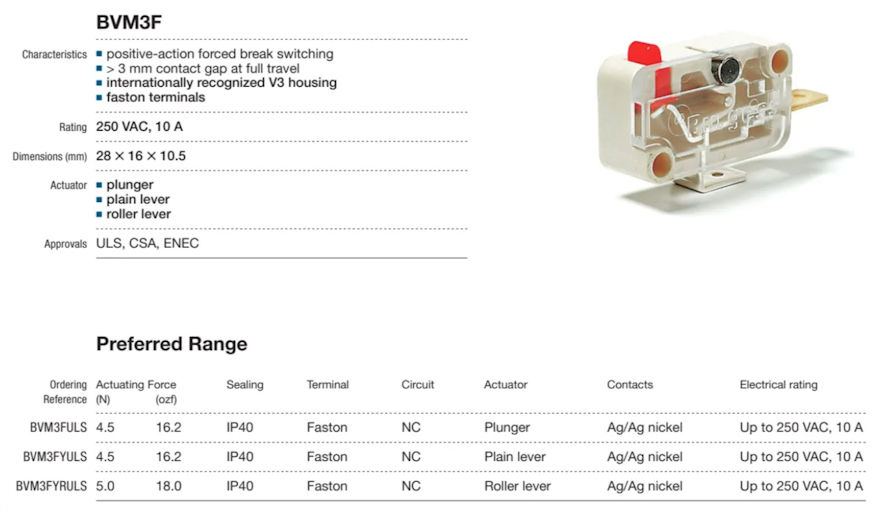

Discover the Power of Precision with the BVM3 Switch Series

Johnson Electric is a leader in microswitch technology, offering precision microswitches under the Saia brand and industrial-rated options under the Burgess brand.

If you are looking for a switch that combines reliability, safety, and versatility, the BVM3 range delivers exceptional performance in a compact design. Engineered for demanding applications, these miniature snap-action switches feature high breaking capacity (up to 250 VAC/10 A), a forced-break mechanism for enhanced safety, and multiple actuator options to fit your design needs.

With proven durability of over 1 million cycles, UL, CSA, and ENEC approvals, and a temperature range from –40 °C to +85 °C, the BVM3 is built to last. Perfect for HVAC, consumer electronics, and automotive systems—upgrade your designs with the switch that sets the standard for reliability.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

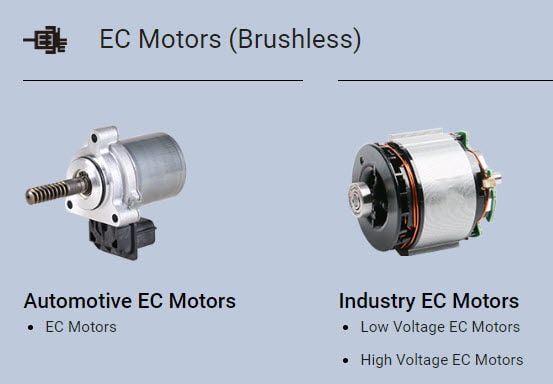

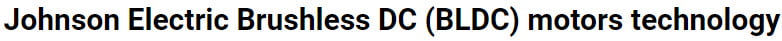

EC motor technology (Electronic Commutation, also called Brushless DC - BLDC) provides high efficiency, long life, and speed control options to motion system designers. Johnson Electric, an industry leader in brushless motor technology has customized EC motors for many

applications in Automotive and Industrial segments.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

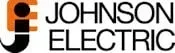

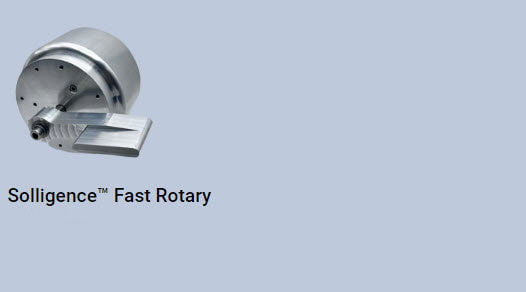

Johnson Electric rotary and linear stepper motors are available in a wide range of sizes and customizable force or torque outputs. Most are available in unipolar or bipolar coil winding configurations.

Our Saia brand of stepper motors is engineered to meet the performance demands of specific applications that require precise position control including valves, HVAC, medical equipment, liquid dispensing and automation. We offer custom engineering to create motion control systems utilizing our precision stepper motors and control electronics, in collaboration with valve and system manufacturers.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

Johnson Electric offers a wide range of power pump subsystems, utilizing various motor technology platforms. Our synchronous, high voltage DC, and EC pumps are engineered for high power, low noise, and long-life performance.

We provide customized applications engineering to adapt and enhance performance based on unique design requirements. With the acquisition of Stackpole International, our automotive pump portfolio now includes engine and transmission pump technologies, complementing our market leadership in fuel and washer pump applications.

Additionally, we deliver durable and reliable valves and cartridges for combi boilers and metering applications, ensuring safety through vertical integration and our proven production system. Trust Johnson Electric for innovative solutions across industrial sectors.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

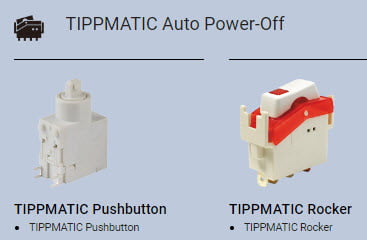

TIPPMATIC® is the latest generation of energy saving automatic shut off switches designed for home technologies, appliances and commercial coffee machines. These technologies exceed the European Eco-Design Directive ErP requirements and reliably eliminates stand-by energy losses in the home and restaurant environment.

The TIPPMATIC product line includes configuration options that address the varied functional requirements of different appliance designs and is customizable for easec of integration. Switches are approved according to the standards of UL 1054, EN 61058-1 and UL 61058-1. Additional approvals such as CSA and CCC are available on request. Approval marks specified in series or product overviews are product related, the exact approval marks are specified on our technical drawings.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

Marketed under the Ledex Brand, Johnson Electric offers a diverse range of rotary and linear solenoids. These industry leading products include our high speed, short stroke rotary actuators such as the BTA and Ultimag series and our long life, medium stroke linear actuators including open frame, tubular and low profile solenoid product families.

From very large rotary versions found in material handling to our smallest open frame linear part numbers used in precision diagnostic equipment, we offer long life, quiet operation, battery operation and magnetic latching solutions. Our broad portfolio of product technologies is custom engineered to meet the requirements of each application.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

Data centers are handling and analyzing enormous amounts of information daily. As data generation increases, the heat generated by the data center indispensably increases. This excess heat generated by data centers can harm the hardware including Central Processing Unit (CPUs) and Graphic Processing Unit (GPUs), reducing their performances, or causing complete failures. To ensure optimal operation, it is crucial to select the right cooling solution.

Market Trends:

According to the (Technavio report 2023), the global market for cooling data centers is projected to increase from USD9.5 billion in 2020 to USD22.6 billion by 2025, with a Compound Annual Growth Rate (CAGR) of 18.0%. However, the high energy consumption associated with data center cooling contributes to increased carbon emissions and energy costs. Therefore, businesses are seeking eco-friendly and energy-efficient cooling technologies, such as free cooling, liquid cooling, and artificial intelligence (AI).

Free Cooling:

One of the most popular methods for cooling data centers is free cooling, which utilizes outer air to cool the center, as opposed to traditional air conditioning. However, technology is not suitable for all climates. For instance, in humid areas, free cooling may cause condensation that damages the hardware or necessitates additional cooling during warmer periods.

Liquid Cooling:

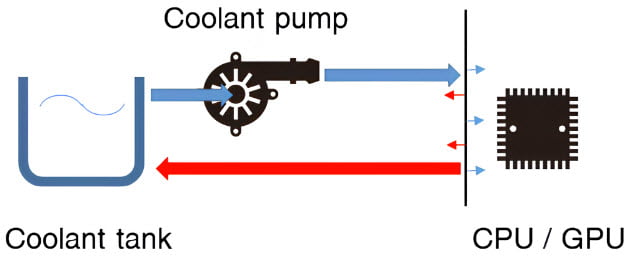

Liquid cooling is gaining popularity in data centers due to its efficiency. Liquid coolant is used to remove heat from the hardware, as liquids offer higher thermal capacity than air resulting in reduced energy consumption. Additionally, liquid cooling fans are quieter than traditional air-cooled fans. As a result, many data centers are turning to this technology to improve their cooling efficiency.

Liquid cooling systems can be classified into two types, namely direct and indirect. Direct liquid cooling involves direct contact between the liquid and hardware, removing heat directly from the source. On the other hand, indirect liquid cooling uses the liquid to cool a heat exchanger, which draws heat from the hardware. Although direct liquid cooling is more effective in removing heat directly from the source compared to indirect liquid cooling, it may require a higher implementation and maintenance cost.

AI-Based Cooling:

AI-based cooling systems utilize sensors to analyze data and optimize temperature and humidity levels within data centers. Furthermore, the systems can predict and prevent potential cooling issues. Implementing AI-based cooling system can reduce energy consumption and enhance cooling efficiency. However, it may involve significant upfront cost and ongoing AI Algorithms development to ensure the accuracy of the real-time data.

In Conclusion, selecting the appropriate cooling solution based on business needs is vital for data centers to ensure optimal performance, reduce energy consumption, and minimize the risk of hardware damage and downtime.

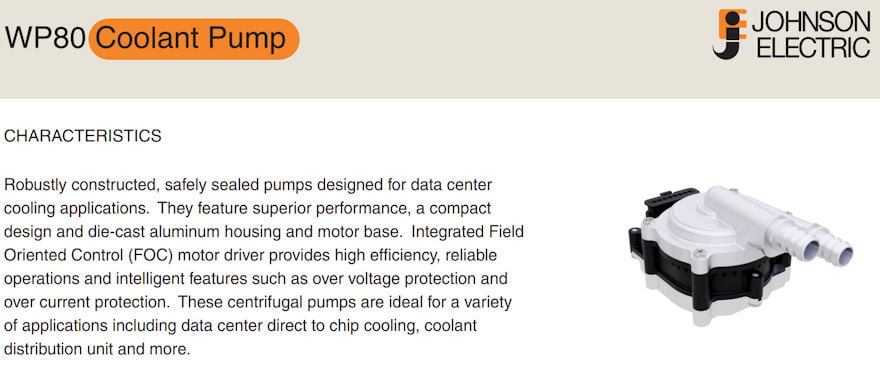

As an industry leader, Johnson Electric offers liquid coolant pumps such as WP80 BLDC Coolant Pump using Brushless DC (BLDC) motors technology and on-board electronic controls that provide intelligent pump operation and safety features.

The Brushless DC (BLDC) motors, with their exceptional features such as speed stability, high efficiency, reliability, and long lifespan, are considered the most suitable option for pump drives in Coolant Distribution Units (CDUs) utilized in data centers. The brushless motor technology is highly compatible with in-row or rack-mounted CDUs and on-board electronic controls, offering intelligent pump operation and safety features for major automotive OEMs and Tier 1 suppliers in Europe, America, and Asia.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

General Use Of Microswitches:

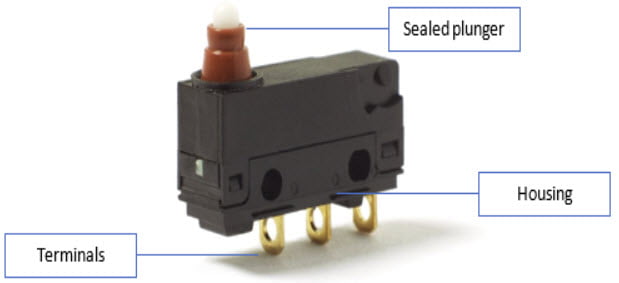

Microswitches have become indispensable in the sensing and control industry for controlling electrical signals. With years of experience, Johnson Electric has supplied billions of microswitches used in home appliances, industrial equipment, automotive applications, agricultural machinery, and control systems worldwide. In most applications, the requirements for the switches are quite simple: they consist of at least two contacts, a common contact with either a normally open contact or a normally closed contact, connected to a snap-action mechanism to switch between the contacts and turn devices on and off. While these switches can operate safely and reliably in general applications, they have limited capabilities in various harsh environments. For this reason, sealed microswitches emerged as a viable solution. Sealed microswitches are basically the same as un-sealed microswitches with the addition of a protection against dust or moisture to enter the switch and reach the contact system.

Microswitches in Home, Industrial, or Automotive Applications:

The requirements for switches, however, can be extremely demanding in environments with high humidity, such as certain household appliances (dishwashers, coffee machines, etc.) or in industrial and automotive applications. Besides water, oil and dust can have a major impact on the applications, sudden temperature changes can also affect the proper functioning. It requires a high degree of sealing to ensure that the switches work without any problems. For example, this sealing should not only withstand the standard temperature range of -40°C to +85°C, but also function at higher temperatures or unexpected temperature drops. These specific applications therefore require a balanced and customized solution in sealing technology, regarding materials, switch- and seal design.

Sealing Technology:

To achieve sealing against dust or water, a "flexible" membrane must be fitted on all switch parts that have an open connection between the internal mechanism of the switch and the outside world. Such parts may be the plunger, the housing parts, or the terminal outputs. In the case of the plunger, the membrane must be flexible; in other areas, a more rigid seal may be sufficient. Consequently, for the microswitch to be manufactured properly and to ensure its function for a long time in harsh environment, the choice of sealing materials is crucial. Adding a seal to a microswitch affects its operating characteristics. In the case of the plunger, adding a seal usually increases the operating force. On the terminals, the seal can limit the soldering time to prevent overheating.

To provide a high-quality seal, Johnson Electric uses either a seal ring mounted separately on the plunger or twin-shot technology to provide housing parts with built-in seals. Different technologies are used for the housing parts and terminals. For example, either by ultrasonic welding of housing parts or by applying a special glue. By applying these solutions, the microswitches can be qualified with the IP67 degree of protection. When open terminals are used, IP protection is limited to the top or plunger side.

Johnson Electric Offer:

Johnson Electric's qualified switches are used to accurately detect the position of mechanical components in industrial and household applications. Additionally, to ensure 360-degree protection of the microswitch, Johnson Electric offers the option of adding moisture protection on the terminal side with lead wires soldered to the switch terminals. These lead wires are then routed through a cable box and potted to ensure IP67 protection on the terminal side. If the switch is UL approved the wires must also be UL approved. The final microswitch product is an IP67-protected switch with an operating temperature range between -40°C and +85°C according to UL61058 and even up to +125°C on demand.

Sealed switches are available in a wide range of sizes and ratings. The most common series are L16, V4NS, F1NS, V3S, 4BR, V9N and TS sealed switch families. Except for the TS, all other switches can be supplied with regular levers or terminals. All mentioned switch families have a UL or/and ENEC approval.

Conclusion:

Johnson Electric can offer you a complete program of sealed switches. The features of these switches include compact size, high lifetime, a high level of protection, and increased electrical properties, etc. There are different types of microswitches, but their selection depends on the requirement. To support you with the correct switch selection please contact our sales department for more information.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

© E. Preston (Electrical) Ltd 2026.

UK distributor of electrical and electronic components.