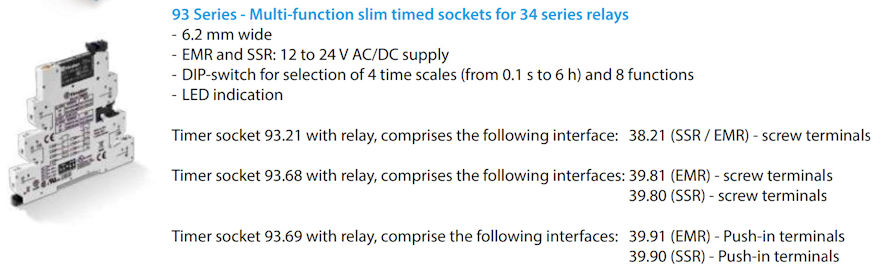

Finder has been active in the design and production of precision electromechanical and electronic components for over 65 years and today boasts a wide range of timers, comprising seven different Series.

Finder’s range of timers is composed of devices for residential, commercial and industrial applications. From opening automatic doors and gates to HVAC systems, each device is designed for maximum precision and easy installation.

The Finder timer range is “Made in Italy “and includes multi-function and multi-voltage devices boasting over 40 different timing functions (depending on the type), such as On-delay, Off-delay, Pulse and Interval timing.

Timers are ideal for the simple, quick “first stage” realization of an automation system or process. Their distinguishing features are:

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

The fuseless motor starters from Eaton's Moeller series have been delivering reliable personal and operational safety in machines and systems for decades.

The motor-starter combinations consist of a motor-protective circuit breaker and a contactor, which can be quickly connected and mounted thanks to the versatile and safe plug-in technology. The compact, fuseless motor starters also make it possible to engineer and build control panels that can be used worldwide.

Connections with just One Clever “Click” – MSC Motor-Starter Combinations with Push-In Technology

The Push-in terminals enable safe and easy control-panel wiring with just one click. Wiring kits for assembly of motor starter combinations up to 32 A are available, with mechanical connecting element and pre-assembled connecting cables for use with DOL starters up to 7.5 kW / 15 kW or reversing starter combinations up to 7.5 kW.

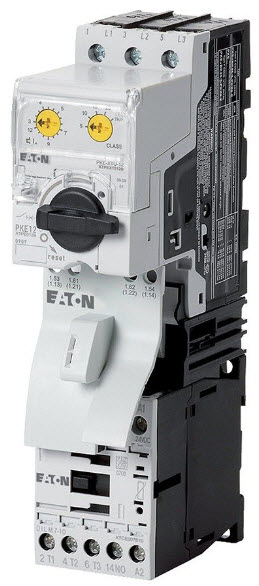

MSC Motor Starters with PKZ up to 32 A

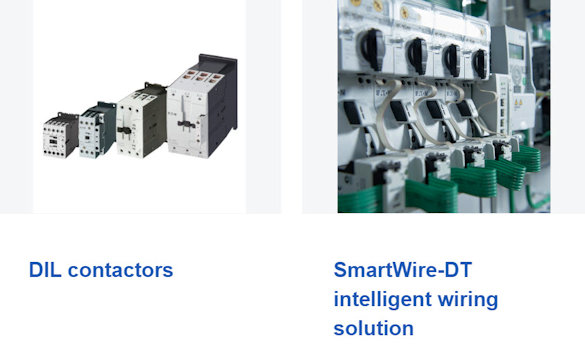

The motor-starter combinations with PKZM0 circuit breaker and DIL contactor are able to handle short circuits up to 50 kA and can be assembled using simple toolless plug connectors. The practical toolless plug connectors are available for Eaton’s DOL and reversing starters up to 15.5 A.

MSC Motor Starters with PKE up to 32 A

The PKE motor-starter combinations can easily be integrated into any automation environment via SmartWire-DT. Data can be transferred directly to the controls and made available across the system. The resulting data transparency increases the efficiency and operational reliability of the drives in the operating environment of the motor-protective circuit breaker.

Smart, Smarter, SmartWire-DT

Our intelligent connection system reduces the wiring costs by up to 85 %. At the same time, it also minimizes installation errors, reduces the planning effort and provides enhanced flexibility during the selection process. The connected devices deliver both analog and digital data, for example on machine states, motor currents or energy consumption.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

Dive into topics such as the efficient E-Box for enhanced productivity, the speed and power of our magnetic and hydraulic circuit breakers, and best practices for electronic vehicle protection.

READ HERE! E-T-A CURRENT Magazine

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

The Schurter NR520R mains socket outlet, as an additional variant to the NR010, NR020 and NR021 models, represents an even more powerful performance to the NEMA mains socket outlet portfolio. The new NR520R complies with UL 498 and CSA C22.2 no. 42.

The higher load capacity of 20 A at 125 VAC makes the NR520R particularly suitable for demanding applications where both high performance and temperature resistance up to 150°C are required. The NR520R mains sockets are ideal for applications in data centers, telecommunications, power distribution and energy management.

The new NR520R power sockets from SCHURTER are designed for particularly efficient snap-in installation and can be wired particularly quickly and easily thanks to IDC and Quick Connect terminals. With these features, the NR520R combines the highest safety and performance standards with time-saving and user-friendly installation. This is particularly interesting for manufacturers of power distribution products. After all: safe, effective and efficient.

The NR520R from Schurter is available in three different colors: black, grey and white. These color options not only offer aesthetic advantages, but also enable targeted adaptation to different environments and areas of application.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

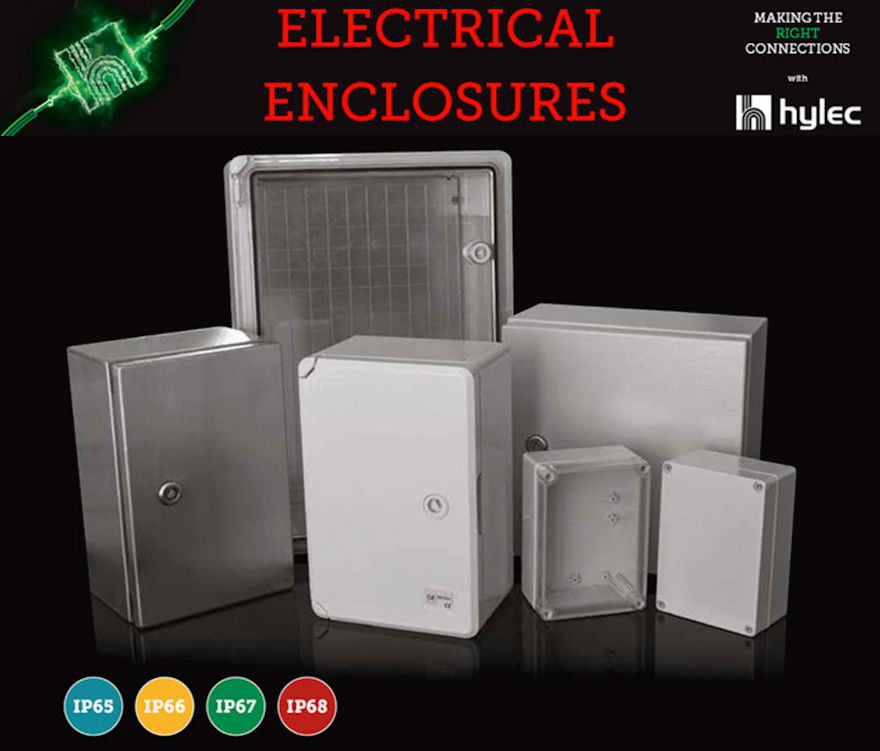

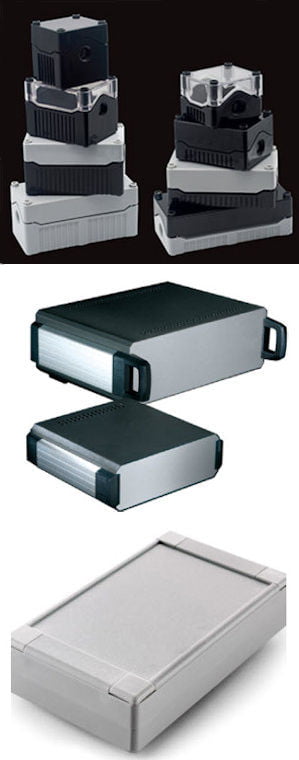

Hylec-APL manufactures a wide range of Electrical Enclosures and Control Equipment, designed to meet the highest standards. Manufactured in a variety of ABS-HB flame retardant plastic, galvanised steel and stainless steel, the range is rated to IP65, IP66, IP67, IK08 and IK10 and the steel range comes with a 3-year corrosion warranty.

Each door enclosure is supplied complete with galvanised mounting plates and screws and also comes equipped with lock and key. The ABS plastic enclosures have an option for transparent doors and the metal door enclosures have pre-wired earth straps.

Finally, there is a wide variety of sizes across the range, certain to cover your requirements.

In addition to the enclosures, Hylec also supplies several ranges of associated equipment that is fully compatible and manufactured to the same high standards. These include isolators, control stations, switching equipment, lamps, filter fans, temperature control equipment, connectors and cable glands. For further information contact our helpful staff.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

The DRC3R Series is a family of DIN Rail Mount, IEC standard based Solid State Contactors with a proprietary thermal management technology, which allows them to handle reversing control of 3-phase motors of up to 5HP at 480 VAC in a compact 45mm wide package. This provides a size reduction of 50% compared to equivalent reversing electromechanical contactors.

The DRC3R Series models include a control interlock feature that allows only Off, Forward and Reverse operation in a safe mode, and they are available with optional embedded auxiliary contacts for additional functionality in your control circuits. They are available with an enhanced 18-30 VDC control input compatible with most solid state type outputs.

Features:

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

Bulgin announce the launch of Waterproof USB Connectors. The Series 20 range of connectors builds on their existing rugged range of USB connectors.

The 20 Series Waterproof USB Connector range, in conjunction with their other panel mount USB connectors, gives engineers and users the opportunity to protect critical components.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

Alternative energy sources are a topic of considerable interest and growth, and this innovative sector is one of the first areas to utilise our sensing solutions.

Our Reed Relays used in Solar Inverters increasing solar panel efficiency, they are also a key component in Fast Charging for electric/hybrid vehicles.

We supply other types of renewable energy producers too, from Float Switches that measure levels in rainwater harvesting tanks and Level Sensors used in steam generators.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

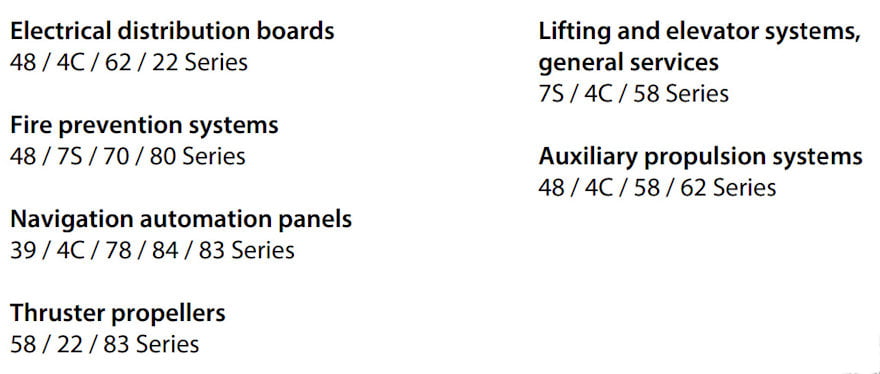

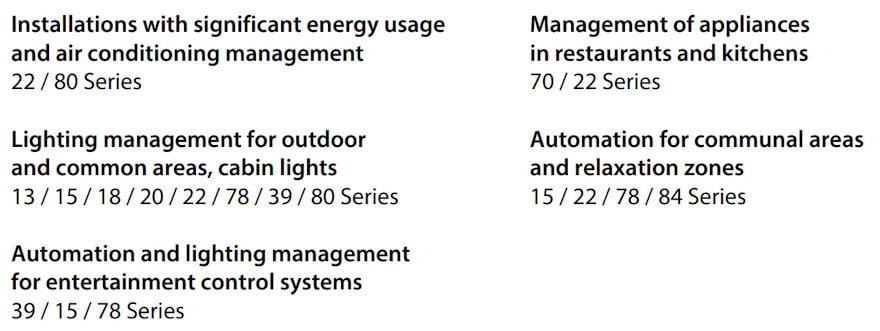

Finder’s range of relays and components

for marine applications includes: high

corrosion resistance and high performance

with operational longevity and reliability,

approved products for the management and

maintenance of equipment on board, lighting

control and cargo monitoring systems,

solutions to improve comfort inside cabins and

much more.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

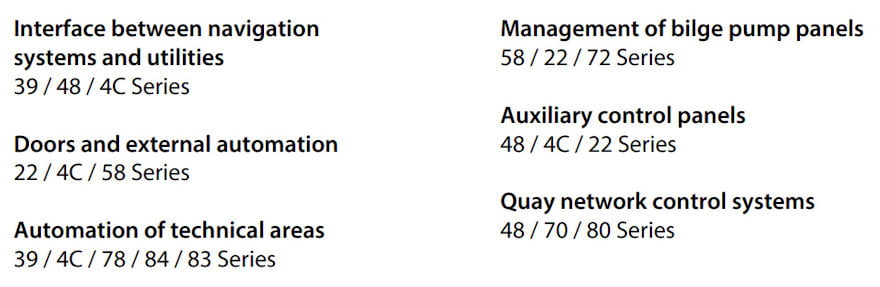

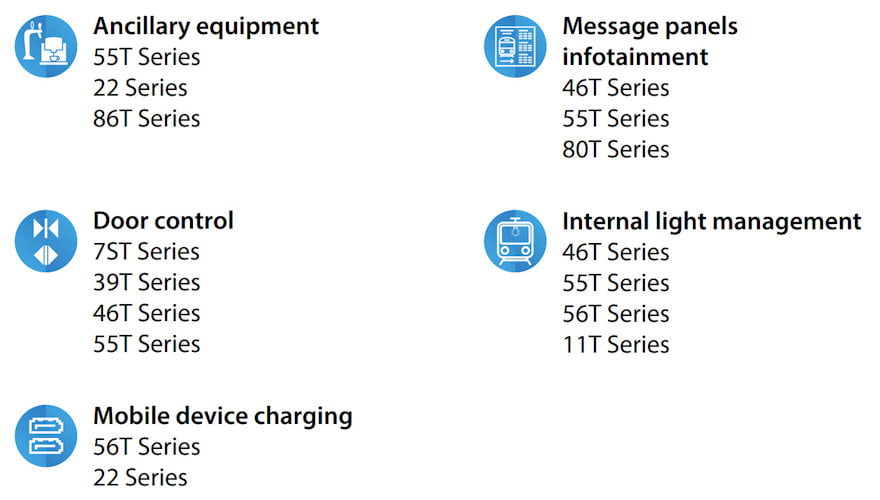

Relays used for railway rolling stock are subject

to increasingly higher technical demands – such

as the need for wider operating ranges; higher

resistance to shock and vibration; operation over

a wider range of temperature and humidity; and

above all, the fire resistance properties of the

relay’s constituent parts.

The resistance against random vibrations and shock of the relays and their sockets and accessories is in compliance with the prescription of EN 61373 standard for Category 1, Class B products.

Their resistance to temperature and humidity is in compliance with the prescription of EN 50155 standard, TX class (for relay and sockets) or T1 class (for timers and control relays).

The relays and their sockets and accessories are manufactured using specific insulating materials, which satisfy the requirement R26 of fire protection prescribed by the standard EN 45545-2 +A1:2016 for product category EL10.

The requirement R26, for Hazardous levels HL1 to HL3, is the conformity to V0 class following vertical small flame test according to EN 60695-11-10.

Enquiry Form: https://www.epreston.co.uk/contact/

Home Page: https://www.epreston.co.uk/epblog/

© E. Preston (Electrical) Ltd 2026.

UK distributor of electrical and electronic components.